The prerequisites for a wall-hung boiler to operate are the connection of water, electricity, and gas. Starting the boiler requires the water pump and boiler fan to be running first, ensuring stable combustion. If the boiler fan malfunctions, the entire boiler will stop working. Troubleshooting boiler fan malfunctions can be approached from the following aspects:

What does a centrifugal blower fan malfunction mean?

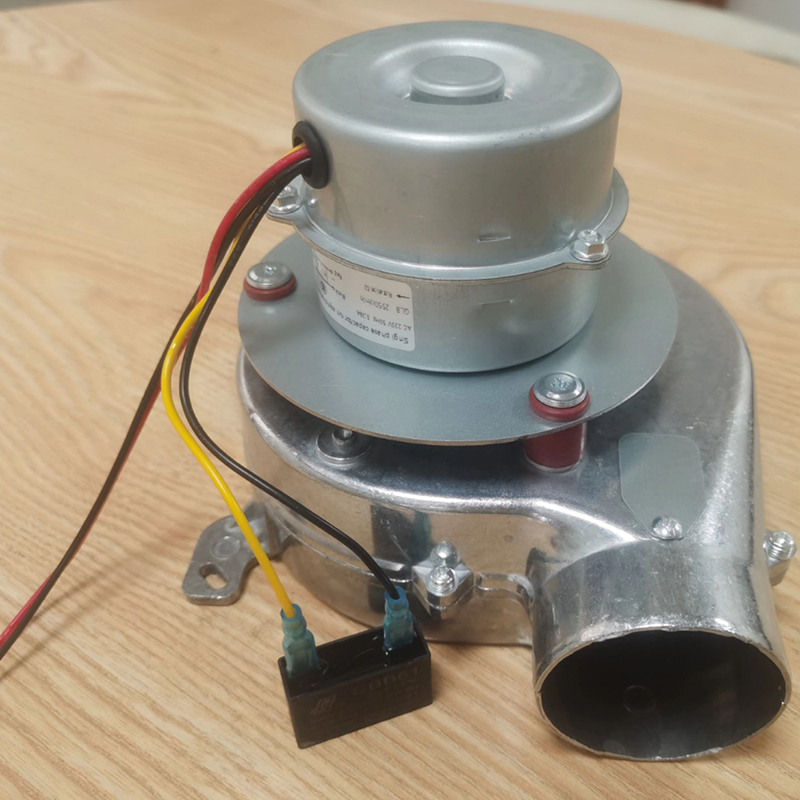

1. The function of centrifugal fans and blowers is to provide fresh air to the boiler fan combustion chamber and then exhaust combustion gases outdoors. Therefore, the flue pipe of a wall-hung boiler uses a coaxial double-layer flue pipe with a diameter of 10 cm. An additional 11 cm is needed for the opening in the glass, and 12 cm is needed for the opening in the wall. The fan operates in a forced balanced mode.

2. Centrifugal fan and blower malfunctions mainly manifest as the boiler fan suddenly stopping or rotating slowly. The boiler will display a fault code for "centrifugal fans and blowers," and the boiler will stop operating due to insufficient ventilation. Therefore, a centrifugal fan and blower malfunction can be diagnosed.

Where are centrifugal blower fan malfunctions most likely to occur?

1. Centrifugal blowers stuck: Centrifugal blowers require a stable rotation speed to operate normally when powered on. When the boiler is located in an environment with severe pollution, such as heavy oil fumes and dust, the blower can easily stop rotating. The most effective solution is to disassemble the centrifugal blowers, rinse them with clean water to remove any adhering substances, and then reassemble them.

2. Centrifugal blower starting capacitor malfunction: While cleaning the centrifugal blowers, also check the starting capacitor of the boiler fan. A damaged capacitor can also cause the boiler fan to stop rotating. In this case, simply replace the capacitor. 3. Loose Connector: The power supply to the boiler's blowers is connected to the starting capacitor via connectors. During operation, there is slight vibration. If the connectors are not properly repositioned during assembly or adjustment, they can slip off, causing the power supply to stop. Simply reinsert the connectors, ensuring they are secure.

3. Missing Fan Impeller: The core component of the blower is the impeller. Its rotation provides sufficient fresh air to the boiler and exhausts waste gas. If the impeller is missing, the fan will rotate unbalancedly and produce noise. The boiler's flue pipe has small holes at the air inlet to prevent large objects from being sucked into the fan. Hard objects can easily break the impeller during rotation, requiring replacement of the entire fan.

If the boiler fan malfunctions, an error code will appear. However, the malfunction of the air pressure switch is somewhat similar to the power outage and gas outage of the wall-hung boiler. If the boiler fails to ignite after frequent restarts, a professional technician needs to come and check the fault. In order to maintain the normal operation of the blower centrifugal, we recommend that users clean and maintain the centrifugal fans and blowers of the wall-hung boiler every 2-3 years. The maintenance of the boiler fan is only one part of this. After maintenance, the wall-hung boiler will have higher combustion efficiency, lower noise, and lower energy consumption.