In modern industry and daily life, the control of air flow and pressure has long transcended the scope of primitive natural phenomena, becoming a precisely adjustable form of energy. From the safe operation of boilers to the ventilation systems of central air conditioners, from the air intake management of automobile engines to the stable operation of household gas water heaters, all rely on a seemingly small yet crucial device — the **air pressure switch**. This precision component, known as the "switch installed for wind", acts like an invisible steward, silently safeguarding the safety and efficiency of countless devices. Its technical principles and application scenarios are far more extensive and profound than we might imagine.

The Invisible Steward in Daily Life: Wind Control Wisdom in Home Appliances

Beyond industrial scenarios, air pressure switches have long penetrated all aspects of daily life, serving as the "safety nerve center" of home appliances. Gas water heaters are the most typical application: when in operation, they require a fan to expel combustion exhaust outdoors. If the flue is blocked or the fan malfunctions, unexpelled exhaust will cause carbon monoxide accumulation, posing a poisoning risk.

The air pressure switch judges whether exhaust is smooth by monitoring the negative pressure generated by the fan. Only when the negative pressure reaches a set value (usually 5-10Pa), confirming the exhaust channel is unobstructed, will the switch activate the gas valve to allow ignition and combustion. Once the negative pressure disappears or drops below the threshold, it immediately cuts off the gas supply — this is what the industry refers to as the "flameout protection" function.

In integrated stoves, the intelligence of air pressure switches is further enhanced. Modern integrated stoves generally adopt "range-hood linkage" technology: when the user ignites the stove, the air pressure switch detects air flow changes caused by flame combustion and automatically starts the exhaust fan. After cooking ends and the stove is turned off, it can delay the fan shutdown by 30-60 seconds based on pressure changes of residual oil fumes in the pipeline, ensuring complete removal of oil fumes. This "on-demand regulation" mode not only improves usability but also reduces energy consumption.

The fresh air handling units in central air conditioning systems also rely on air pressure switches for intelligent operation. When filter dust accumulation increases air intake resistance, the switch triggers a filter cleaning reminder. When outdoor fresh air pressure is too high (e.g., during strong winds), it can automatically adjust the air valve opening to prevent excessive cold air or pollutants from entering the room. In air purification systems of high-end buildings, air pressure switches can even cooperate with PM2.5 sensors to dynamically adjust fresh air volume based on air cleanliness, achieving energy-saving "on-demand air supply".

The Art of Selection: How to Choose the Right "Switch" for Wind

Faced with a wide variety of air pressure switch products on the market, choosing the appropriate model has become a practical problem for users.

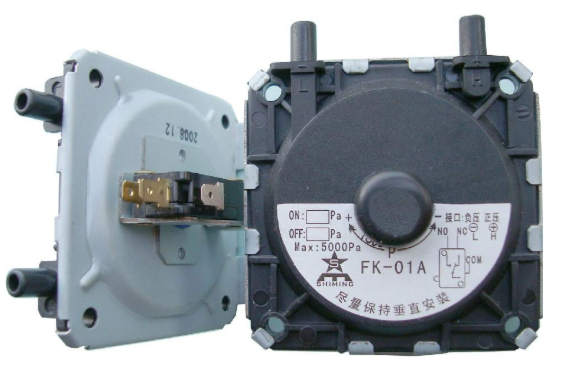

First, clarify the pressure range of the application scenario. Different devices have significantly different air pressure requirements: the air pressure for gas water heaters is usually within ±50Pa, while that for industrial boilers can reach ±5000Pa. When selecting, ensure the switch’s measurement range covers the actual working pressure, and the optimal measurement point falls within the 1/3-2/3 range of the full scale.

Second, consider environmental adaptability. For humid environments (e.g., bathrooms), choose products with an IP65 or higher protection rating. For high-temperature environments (e.g., near boilers), pay attention to the switch’s maximum operating temperature. In occasions with corrosive gases, switches with corrosion-resistant diaphragms are a must. A food processing plant once used ordinary air pressure switches to monitor steam pipeline pressure, leading to diaphragm corrosion by steam and equipment shutdown due to false signals. The problem was completely resolved after replacing with stainless steel temperature-resistant switches.

For systems with high intelligence requirements, prioritize intelligent air pressure switches with digital communication functions. These products not only provide accurate pressure data but also seamlessly connect with control systems via protocols such as Modbus and 485, enabling remote monitoring and automatic adjustment. In building automation systems (BAS), the linkage between intelligent air pressure switches and BA (Building Automation) systems greatly improves the operating efficiency and management convenience of the entire ventilation system.

The convenience of installation and maintenance should also not be overlooked. Choosing products with standard interfaces (e.g., G1/4 threads) simplifies the installation process. Switches with modular design do not require disassembly of the entire pipeline system when replacement is needed, significantly reducing maintenance costs. Regular calibration is equally important — it is recommended to calibrate the accuracy of the air pressure switch once a year to ensure its measurement error remains within the allowable range.

From industrial boilers to household water heaters, from large buildings to aerospace equipment, air pressure switches, with their unique ability to "control the large with the small", have installed precisely adjustable "switches" for invisible wind. This seemingly ordinary component embodies the wisdom of fluid control, safeguards the safety of production and life, and promotes the efficiency of energy utilization. When we enjoy the warmth from water heaters in winter, witness the orderly operation of production lines in workshops, or breathe clean air in buildings, we may not be aware of the existence of air pressure switches. However, it is these invisible "wind stewards" that, through the power of technology, make invisible air flow measurable, manageable, and reliable, demonstrating the sophistication and dependability of modern industry in a small space.