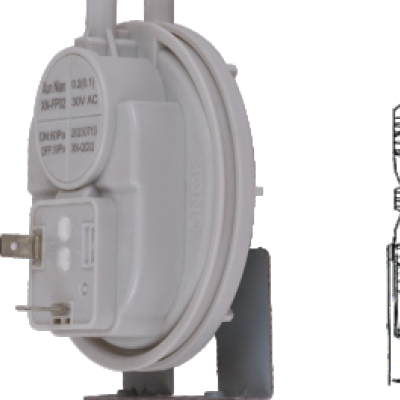

As an important device, the pressure switch plays a significant role in multiple fields. It can control the on-off of circuits through pressure changes in the system, thereby realizing automatic control of equipment. The pressure switch acts as a "controller" in equipment such as air compressors and water pumps. Regular maintenance of the pressure switch is required to ensure its normal operation and extend its service life. This article mainly introduces some detailed maintenance items for the pressure switch.

I. Daily Cleaning and Inspection

Daily cleaning is the basic work for the maintenance of the pressure switch. During the cleaning process, first of all, ensure that the equipment is in a power-off state to avoid safety accidents such as electric shock. You can use a dry and soft cloth to gently wipe the surface of the pressure switch to remove dust, oil stains and other impurities. For some gaps or hard-to-clean parts, compressed air can be used for blowing, but attention should be paid to controlling the air pressure to avoid damaging the switch due to excessive pressure.

At the same time, careful inspection should be carried out during the cleaning process. Observe whether the appearance of the pressure switch is damaged, deformed, cracked, etc., whether the screws at the connection parts are loose, and whether the wiring is firm, aged or damaged. If loose screws are found, they should be tightened in time with appropriate tools; for aged or damaged wiring, they should be replaced in time to ensure the reliability of the circuit connection.

II. Pressure Indication Check

Observe whether the pressure indication of the pressure switch is accurate and consistent with the actual pressure value. Professional pressure detection equipment can be used for comparative measurement. If there is a deviation in the pressure indication, it may be that the pressure sensor is faulty and needs to be calibrated or replaced. In addition, it is necessary to check whether the scale of the pressure indication is clear. If the scale is blurred, it may cause difficulties for operators in reading and should be dealt with in time.

III. Environmental Control

The working environment of the pressure switch has a great impact on its performance and service life, so it is necessary to effectively control the working environment.

First of all, avoid the pressure switch being in an overly humid environment. A humid environment can easily cause rust and corrosion of the internal components of the switch, affecting its conductivity and operational flexibility. If the humidity in the working environment is high, measures such as installing dehumidification equipment and sealing the pressure switch can be taken to reduce the environmental humidity.

Secondly, prevent the pressure switch from being subjected to severe vibration and impact. Severe vibration and impact may cause loosening and damage of the internal components of the switch, affecting its normal operation. When installing the pressure switch, a stable and firm position should be chosen, and necessary shockproof measures, such as installing shockproof pads, should be taken.

In addition, avoid the pressure switch coming into contact with corrosive gases, liquids or dust. These substances can corrode and damage the metal parts and insulating materials of the switch, shortening its service life. If there are such harmful substances in the working environment, effective protective measures should be taken, such as installing protective covers and carrying out regular cleaning.

IV. Internal Cleaning

Since dust and impurities may accumulate inside the pressure switch, affecting its performance, regular internal cleaning is necessary. Before carrying out internal cleaning, the power must be cut off to ensure operational safety. After opening the switch shell, compressed air or a small brush can be used to gently clean the internal dust and debris. During the cleaning process, care should be taken to avoid touching the sensitive components of the switch to prevent damage.

V. Fault Handling and Maintenance

When a fault occurs in the pressure switch, it should be dealt with in time to avoid the fault from expanding. When handling the fault, first of all, carefully observe and analyze the fault phenomenon to determine the cause of the fault. If the fault is caused by wear or damage of internal components, the corresponding components need to be replaced in time. When replacing components, products that are consistent with the specifications and models of the original components should be selected to ensure the performance of the switch.

For some more complex faults, such as circuit faults, professional maintenance personnel should be invited to handle them to avoid greater losses caused by improper self-repair. After the fault is handled, a comprehensive inspection and debugging of the pressure switch should be carried out to ensure that it can work normally.

The pressure switch needs systematic maintenance from aspects such as daily inspection and cleaning maintenance to ensure its normal use, improve the reliability and stability of the equipment, and provide a strong guarantee for production and life.