In the field of ventilation equipment, "high efficiency" and "low noise" are often regarded as two core requirements that are difficult to balance. Traditional fans either sacrifice quiet performance for large air volume, resulting in constant rumbling during operation; or compromise ventilation efficiency to reduce noise, making it hard to meet the needs of high-load scenarios. However, this 65W high-efficiency centrifugal fan for mechanical ventilation, known as the quiet "Little Powerhouse", breaks this dilemma with its innovative design. It not only lives up to the "Little Powerhouse" title with its powerful performance but also interprets the true meaning of "quietness" through ultra-low noise, becoming a preferred equipment for ventilation systems in many industries.

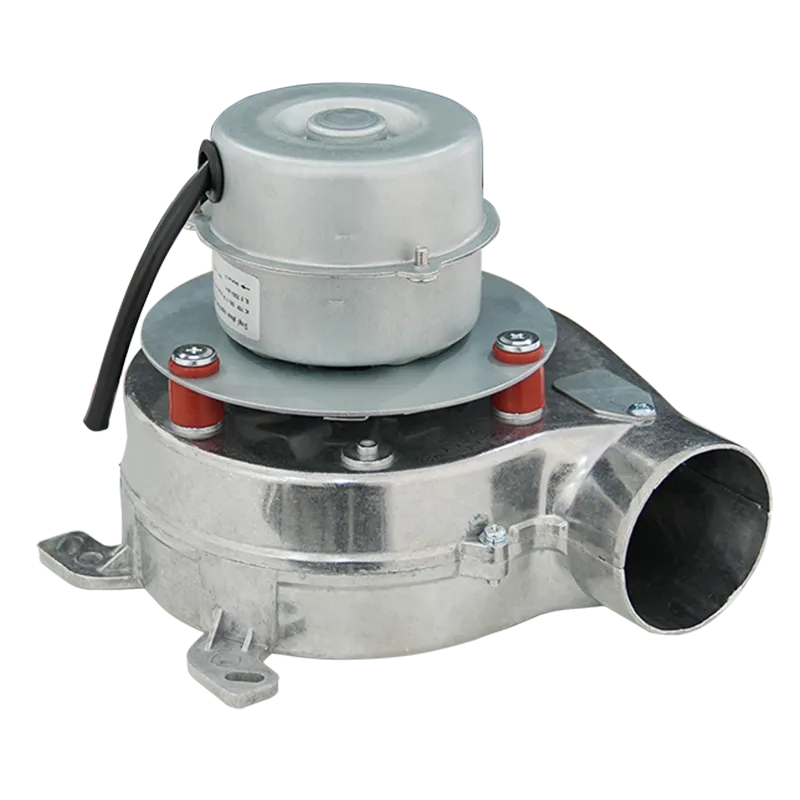

From the perspective of core performance, the "high efficiency" of this fan stems from sophisticated technical refinement. Equipped with a 65W high-efficiency motor, it adopts an optimized electromagnetic structure design, whose electrical energy conversion efficiency far exceeds the industry average. Under the same power, it can output more stable power. Cooperated with a customized centrifugal impeller — the impeller blades are optimized through fluid dynamics simulation, with their curvature and angle accurately matching the airflow trajectory — this design effectively reduces the collision and loss of airflow inside the impeller.It not only increases the air volume by more than 15% but also maintains stable air pressure to cover medium and high-pressure scenarios, easily meeting the needs of equipment heat dissipation and local ventilation. Whether for heat dissipation of industrial equipment cabinets or auxiliary smoke exhaust for commercial kitchen appliances, it can achieve high-efficiency ventilation with low power consumption of 65W, which not only reduces energy costs but also avoids the circuit load pressure caused by high-power equipment.

The advantage of "quietness", on the other hand, comes from in-depth control of noise sources. The noise generated by the fan during operation mainly comes from two core factors: motor vibration and airflow disturbance. To address this, the R&D team installed a multi-layer shock absorption and buffering structure outside the motor, using high-elasticity quiet materials. This structure can effectively absorb the vibration generated by the motor during operation, preventing vibration from being transmitted to the installation carrier through the fan body and reducing structural sound transmission. At the same time, both the air inlet and outlet of the fan are designed with streamlined air guide channels, whose inner walls are covered with sound-absorbing cotton. When airflow passes through, it can be fully guided and muted, avoiding harsh turbulent noise caused by disordered airflow. Professional testing shows that the noise level of this fan under rated working conditions is only below 45 decibels, which is equivalent to the volume of soft indoor conversation. Even when used in noise-sensitive scenarios such as laboratories and medical equipment rooms, it can maintain a quiet and comfortable environment.

As a ventilation device specially designed for mechanical scenarios, this "Little Powerhouse" also has excellent adaptability and durability. Its body is integrally formed with high-strength engineering plastics, which not only has light weight for easy installation but also features corrosion resistance and high-temperature resistance. It can adapt to complex working conditions such as dusty industrial workshops and high-temperature oil fume environments in kitchens, with a service life of more than 8,000 hours. Meanwhile, the fan's installation interface is designed in a standardized manner, compatible with ventilation ducts of various sizes. Whether it is wall-mounted, horizontal or vertical installation, it can be quickly adapted, reducing the cost of later modification and maintenance.

From the perspective of practical application scenarios, the value of this fan has long penetrated into multiple fields: in the electronic manufacturing industry, it provides efficient heat dissipation for precision instrument cabinets, preventing equipment shutdown due to high temperatures; in the commercial catering industry, it assists the smoke exhaust system to improve smoke control effects, while its low-noise feature does not affect the dining experience in restaurants; in the medical equipment field, it provides protection for the internal ventilation of testing instruments, operating quietly without interfering with medical operations. It can be said that this quiet "Little Powerhouse" — the 65W High-Efficiency Centrifugal Ventilation Expert — has redefined the performance standards of small centrifugal fans with its core advantages of "high efficiency without disturbing people, quietness without low efficiency", and provides a solution that combines practicality and comfort for the ventilation needs of more industries.