In modern industrial automation and daily life, pressure switches, as core components of pressure control, act like invisible "safety guards", silently ensuring the stable operation of various equipment. From water pressure regulation in household water heaters to high-pressure pipeline monitoring in petrochemical industry, from air pressure control in medical equipment to precision pressure regulation in aerospace engineering, pressure switches can be found everywhere.

Basic Principles of Pressure Switches

Essentially, a pressure switch is a "pressure-triggered controller", whose core function is to convert gas pressure signals into electrical switch signals. Regardless of the type, all pressure switches follow the three-step working logic of "detection - comparison - execution": first, capture pressure changes through sensing elements, then compare the measured pressure with a preset threshold, and finally drive the switch to turn on or off through mechanical or electronic means.

The choice of sensing elements directly determines the performance characteristics of the pressure switch. As the most traditional sensing element, springs transmit pressure signals through elastic deformation, which are low in cost but limited in precision. Diaphragm-type sensing elements use thin metal or rubber sheets, which are sensitive to small pressure changes and often used in low-pressure scenarios. Bellows achieve pressure sensing through a retractable tubular structure, combining sensitivity and pressure resistance, making them an ideal choice for medium and high-pressure fields. These elements are like the "nerve endings" of the pressure switch, converting invisible pressure into measurable physical displacement or electrical signals.

The difference in triggering mechanisms is the key to distinguishing types of pressure switches. Mechanical triggering relies on mechanical structures such as levers and buckles to realize switch actions through physical contact; electronic triggering uses changes in the electrical properties of semiconductor devices to achieve contactless control. Each mechanism has its own advantages and disadvantages: mechanical triggering has strong anti-interference ability, while electronic triggering has a fast response speed, and together they form the technical branches of pressure switches.

Types of Pressure Switches

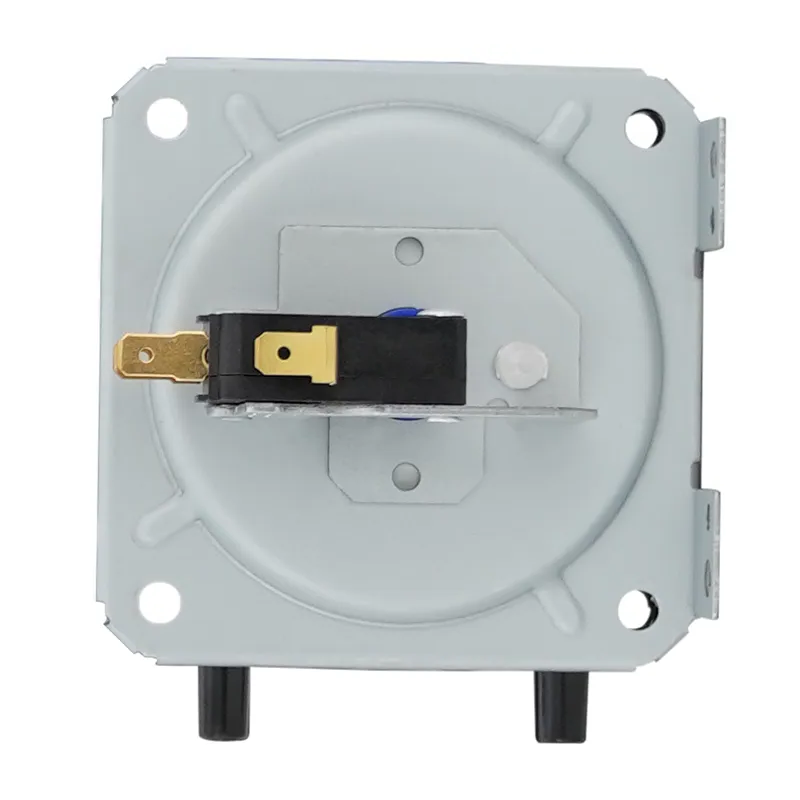

Mechanical Pressure Switches

Mechanical pressure switches are the most common type of pressure switch, mainly composed of pressure sensors, elastic elements, and micro switches. Its working principle is based on the deformation of the elastic element under air pressure. When the deformation reaches a certain degree, it pushes the micro switch to act, thereby realizing the on-off control of the circuit.

Electronic Pressure Switches

With the continuous development of electronic technology, electronic pressure switches have gradually been widely used. It uses a pressure sensor to convert air pressure signals into electrical signals, which are then processed and compared by electronic circuits, and finally controls the on-off of the circuit.

Bellows-Type Pressure Switches

Bellows-type pressure switches use bellows as elastic elements. Bellows are made of materials such as metal or plastic, with large displacement and high sensitivity. When the air pressure changes, the bellows will expand and contract, driving the micro switch to act. Compared with diaphragm-type pressure switches, bellows-type pressure switches have higher precision, better stability, and can adapt to a wider range of air pressure. They are often used in occasions requiring high precision of air pressure control, such as industrial automation production lines and precision instruments. However, the manufacturing process of bellows is relatively complex and the cost is high, which limits its application range to a certain extent.

Diffused Silicon Pressure Sensor-Type Pressure Switches

Diffused silicon pressure sensor-type pressure switches use diffused silicon pressure sensors to detect air pressure. Diffused silicon pressure sensors have the advantages of high precision, good linearity, and fast response speed. They generate electrical signals by detecting the strain of the silicon diaphragm under air pressure. After processing such as amplification and compensation, the signals are compared with the set threshold. When the air pressure reaches the set value, a control signal is output. This type of pressure switch has high reliability and stability, can achieve precise air pressure control, and is widely used in industrial automation, aerospace and other fields. However, its price is relatively high, and it has strict requirements on the operating environment, such as the need to avoid harsh environments like high temperature and humidity.

Different types of pressure switches have obvious differences in structure, principle, performance, and applicable scenarios. Choosing a suitable pressure switch is not only a technical decision but also a strategic consideration for production safety and efficiency. When selecting a pressure switch, it is necessary to comprehensively consider factors such as specific application requirements, working environment, and control precision to ensure that the most appropriate pressure switch is chosen, providing a reliable guarantee for the normal operation of equipment and the smooth progress of production and daily life.