The adjustment and selection of air compressor pressure switches are crucial for ensuring equipment normal operation and safe production. The relevant methods are described in detail as follows:

Selection Methods

- (1) Selection Based on Compressor Type

Different types of air compressors (such as reciprocating piston, rotary vane, and centrifugal) have varying requirements for pressure switch types and parameters. For example, reciprocating piston air compressors are typically suitable for small to medium-scale pneumatic tools and equipment, and their pressure switches need to adapt to intermittent operation and significant pressure fluctuations.

- (2) Selection Based on Application Scenarios

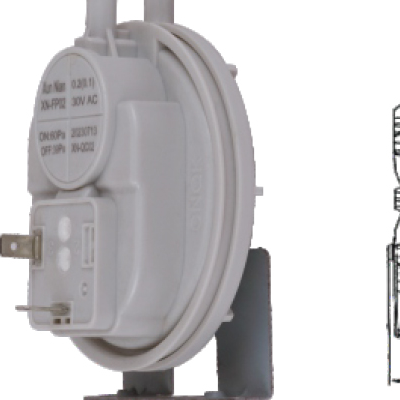

- General Industrial Scenarios: For workshop air supply, small spraying equipment, etc., mechanical pressure switches (such as diaphragm or bellows types) are preferred for low cost and easy maintenance.

- Precision Instruments & Automated Production Lines: When high pressure control accuracy (e.g., ±0.01MPa) or remote monitoring/data transmission is required, electronic pressure switches are prioritized, which can be integrated with PLC systems for automated control.

- High-Pressure or Special Medium Scenarios: When the system pressure exceeds 1.6MPa or the compressed medium is corrosive gas, high-pressure or anti-corrosion pressure switches should be selected, with materials like stainless steel or engineering plastic.

- (3) Attention to Switch Response Speed

In scenarios requiring rapid pressure control response (e.g., pneumatic control systems in automated production lines), pressure switches with fast response speed must be chosen to timely and accurately control compressor start/stop, ensuring stable system operation.

- (4) Confirmation of Rated Parameter Matching

- Rated Pressure: The maximum withstand pressure of the pressure switch should exceed the highest possible system pressure, generally 1.5-2 times the system's maximum pressure. For example, if the system's highest pressure is 1.0MPa, select a switch with a rated pressure of 1.6MPa or above.

- Contact Capacity: It must match the voltage and current of the control circuit to avoid contact burnout from excessive load. Common contact capacities are AC 220V/10A or DC 24V/5A. For heavy loads, expand contact capacity via an intermediate relay.

- Brand and Quality: Choosing well-known brands and reliable pressure switches ensures stable performance, long service life, and timely after-sales support in case of failures.

Adjustment Operation for Mechanical Pressure Switches

1. Pressure Relief and Shutdown: Ensuring Safety

The first step is to shut down the air compressor, then open the system exhaust valve and wait for the pipeline pressure to gradually drop to zero. This critical step avoids safety risks caused by residual pressure during adjustment, creating a safe operation environment.

2. Identification and Positioning of Adjustment Screws

Mechanical pressure switches typically have two key adjustment components:

1. Main Spring Adjustment Screw: Controls the overall range of start/stop pressure. Clockwise rotation increases the pressure setting, while counterclockwise rotation decreases it.

2. Differential Pressure Adjustment Screw: Specifically adjusts the difference between start and stop pressures. Clockwise rotation increases the differential pressure, and counterclockwise rotation decreases it.

Some pressure switch models mark "MAX" (maximum) or "MIN" (minimum) beside the adjustment screws, or include simple diagrams to help operators quickly identify adjustment directions and functions.

3. Precise Pressure Setting Process

(1) Stop Pressure Setting

1. Slowly rotate the main spring adjustment screw with appropriate tools while closely monitoring the pointer on the pressure switch dial or the external pressure gauge.

2. Rotate clockwise to gradually increase the pressure setting, or counterclockwise to decrease it.

3. Precisely adjust the stop pressure (i.e., the system's maximum working pressure) to the required value, such as 0.8MPa.

(2) Differential Pressure Adjustment and Start Pressure Determination

1. After setting the stop pressure, adjust the differential pressure screw with specialized tools.

2. Rotate clockwise to increase the differential pressure, or counterclockwise to decrease it.

3. Taking a stop pressure of 0.8MPa and a differential pressure of 0.2MPa as an example, the start pressure is calculated as 0.6MPa (0.8MPa - 0.2MPa).

4. After adjustment, simulate pressure changes by manually pressing the pressure switch's elastic element (e.g., diaphragm, bellows) or using an external air source, and repeatedly test to confirm that the contacts act accurately at the set pressure values.

4. Fixing with Lock Nuts: Stabilizing Settings

Once all adjustments are completed and verified through multiple tests, the final step is to tighten the lock nuts on the adjustment screws. This is essential because during compressor operation, vibrations may cause the screws to loosen, leading to setting deviations. Lock nuts ensure the pressure switch operates stably according to the set parameters for a long time. Additionally, clearly mark the set parameters (e.g., stop pressure, start pressure, differential pressure) near the pressure switch for easy future maintenance and troubleshooting.

Proper selection and adjustment of pressure switches not only ensure efficient compressor operation but also extend equipment life, reduce energy consumption, and avoid safety accidents caused by abnormal pressure, which is of great significance for industrial production stability and economy. In practical operations, it is recommended to refer to equipment manuals or consult professional technicians to ensure safe adjustment processes and reasonable parameter settings.