An AC centrifugal fan is a fluid machinery that transports gas by virtue of centrifugal force, widely used in ventilation, air conditioning, boilers and other fields. Its structural design and working principle focus on "converting electrical energy into gas kinetic energy and pressure energy", featuring high efficiency and stability.

I. Core Structural Composition

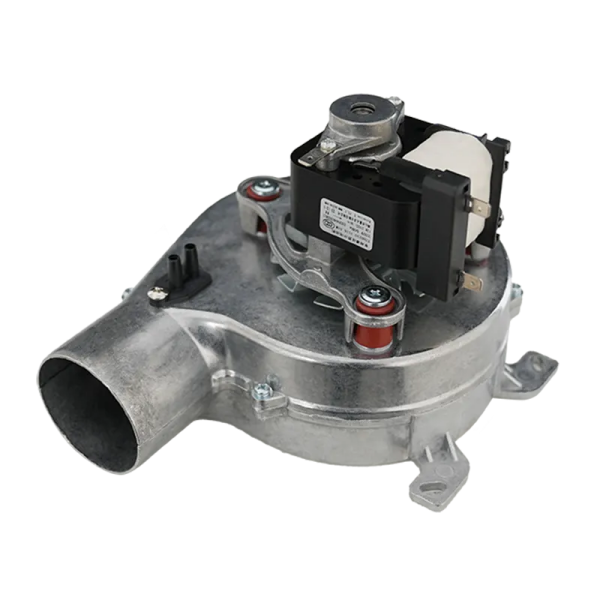

The structure of an AC centrifugal fan can be divided into two major parts: the power system and the fluid conveying system. All components work together to realize gas transportation:

1. Power System: Providing Rotational Power

- AC asynchronous motor: The "power source" of the fan, which converts electrical energy into mechanical energy based on the principle of electromagnetic induction. When three-phase alternating current is applied, the stator generates a rotating magnetic field, and the rotor rotates under the action of the magnetic field force. The rotation speed is usually 1500-3000 revolutions per minute (affected by the power frequency), and the impeller is driven to rotate through a coupling.

- Transmission device: Including couplings or pulleys, which are used to connect the motor and the impeller to transmit rotational power. Some small fans directly install the impeller on the motor shaft to simplify the structure.

2. Fluid Conveying System: Realizing Gas Acceleration and Pressurization

- Impeller: The core working component, composed of a hub and blades. Blades are classified into forward-curved, backward-curved (commonly used) and radial types according to their shapes. Backward-curved blades are widely used in scenarios requiring stable wind pressure (such as boilers) due to their high wind pressure and low resistance (with an efficiency of over 80%). When the impeller rotates at high speed, the blades push the gas to make circular motion, generating centrifugal force.

- Volute: A spiral shell surrounding the impeller, whose function is to "collect and convert energy". Its cross-section gradually expands from the outlet of the impeller. According to Bernoulli's principle, the air flow speed decreases, and kinetic energy is converted into static pressure energy, so that the gas obtains stable pressure and is discharged from the air outlet.

- Air inlet: Mostly designed in a conical shape, it guides air to enter the impeller smoothly, reduces air flow disorder and eddy current loss, and improves air intake efficiency.

II. Working Principle: Gas Flow Driven by Centrifugal Force

The working process of an AC centrifugal fan can be divided into three stages: gas inhalation, acceleration and pressurization, and discharge. The core is to realize the energy conversion of gas by using centrifugal force:

1. Gas inhalation: When the motor drives the impeller to rotate at high speed, a low-pressure area is formed in the central area of the impeller, and the external gas is sucked into the impeller through the air inlet under the action of atmospheric pressure.

2. Centrifugal acceleration and pressurization: The gas entering the impeller is pushed by the blades, makes circular motion with the impeller, and is "thrown" to the edge of the impeller under the action of centrifugal force. At this time, the gas gains kinetic energy (increased speed), and in the volute, the kinetic energy is converted into static pressure energy through the expansion of the cross-section, resulting in increased pressure.

3. Directional discharge: The pressurized gas flows along the spiral path of the volute and is finally discharged from the air outlet to complete gas transportation.

III. Key Characteristics: Regulation of Wind Pressure and Air Volume

- Wind pressure: The pressure generated by the fan is used to overcome the resistance of pipelines and equipment. The backward-curved blade design can provide higher wind pressure at the same rotation speed.

- Air volume: The volume of gas delivered per unit time is positively correlated with the impeller rotation speed. By adjusting the motor rotation speed (such as frequency conversion technology), the air volume can be accurately controlled to adapt to different working conditions and reduce energy consumption at the same time.

In summary, AC centrifugal fans drive the impeller to rotate through the motor, and realize the inhalation, acceleration and pressurization of gas by using centrifugal force. Their structural design (especially the impeller and volute) directly affects efficiency and performance, making them the core equipment for gas transportation in industrial and civil fields.