In our daily lives and work, countless invisible airflows move silently: the exhaust gas from gas water heaters, the oil fumes sucked away by integrated stoves, the combustion-supporting air in industrial boilers... These airflows seem disorderly, but they all operate in an orderly manner under the command of an "invisible commander" — the gas pressure switch. This small component hidden inside equipment has no striking appearance, yet it can accurately "read" the state of airflows and control equipment start/stop and adjust airflow intensity by "issuing orders," becoming a key force in safeguarding safety and efficiency.

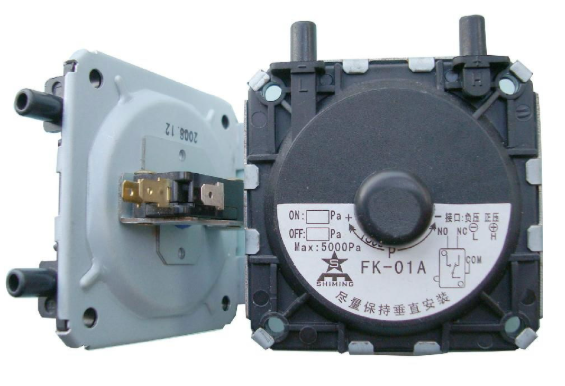

The reason why the gas pressure switch is called the "Airflow Commander" lies first in its keen "perception ability" to accurately capture subtle changes in airflows. Its core "sensory organ" is a thin yet tough diaphragm, with both sides connected to a "pressure measurement port" and a "reference port" respectively: the pressure measurement port faces the airflow to be monitored directly, while the reference port maintains a stable atmospheric pressure. When the airflow moves, the pressure measurement port is subjected to pressure, causing the diaphragm to deform slightly; once the deformation reaches a preset level, the internal lever mechanism is triggered, transmitting signals of "airflow up to standard" or "abnormal airflow."

This "perception ability" is fully demonstrated in gas water heaters. When the water heater starts, the fan first operates to generate negative-pressure airflow, which acts on the diaphragm of the gas pressure switch. When the pressure difference on both sides of the diaphragm reaches 5-10Pa (equivalent to the pressure of a feather falling on the skin), the gas pressure switch "determines" that the airflow is normal and sends an order of "ignition allowed" to the control system; if the fan malfunctions and the airflow is interrupted, the diaphragm does not deform, and the switch "forbids" ignition, preventing the risk of carbon monoxide poisoning caused by stagnant exhaust gas at the source. Here, the gas pressure switch is like a rigorous commander — it only allows subsequent procedures to start after confirming that "the airflow channel is unobstructed."

In the exhaust system of integrated stoves, the gas pressure switch’s "command ability" is even more flexible. During cooking, integrated stoves rely on strong airflow to suck away oil fumes, but once the exhaust pipe is blocked by oil stains, the airflow speed drops sharply. At this time, the gas pressure switch can quickly "detect" the pressure change and immediately issue two "orders": first, trigger an alarm to remind the user to clean the pipe; second, automatically reduce the heat of the gas stove to reduce oil fume production. This dual order of "early warning + risk control" not only prevents oil fumes from flowing back and polluting the kitchen but also avoids equipment damage due to overload, perfectly interpreting the overall planning ability of a "commander."

Even in industrial scenarios, the "command authority" of the gas pressure switch cannot be underestimated. Take the boiler of a thermal power plant as an example: the furnace requires the cooperation of stable combustion-supporting air and exhaust airflow to ensure full combustion of fuel. The gas pressure switch continuously monitors the pressure difference inside and outside the furnace: if the air intake is insufficient (low pressure), it will issue an order to "increase the fan speed" to supplement airflow; if the exhaust is blocked (high pressure), it will order to "open the pressure relief valve" to dredge the airflow. It is under its precise command that the boiler can always maintain the optimal combustion state, ensuring power generation efficiency while avoiding safety accidents caused by chaotic airflows.

However, such a "key commander" is often overlooked by people. On one hand, it is hidden inside equipment and cannot be observed directly with the naked eye; on the other hand, its failure rate is extremely low, and long-term stable operation makes people gradually forget its existence. But once it "goes on strike," the consequences are unimaginable: a food processing plant once suffered a fire due to stagnant airflow in drying equipment caused by a faulty gas pressure switch, which led to the accumulation of high-temperature air; a gas boiler in a residential area had insufficient air intake due to a failed gas pressure switch, resulting in incomplete gas combustion and the smell of carbon monoxide permeating the entire building. These cases all confirm that without this "Airflow Commander," the disorderly flow of airflows will instantly turn into a safety hazard.

What is even more commendable is that with the development of technology, the "command level" of modern gas pressure switches is constantly upgrading. Intelligent gas pressure switches can not only transmit orders accurately but also record airflow data and upload information to the cloud via the Internet of Things. Maintenance personnel can check the airflow status of different equipment in real time through their mobile phones and predict the operation risks of the gas pressure switch in advance — this is like equipping the "commander" with a "data staff officer," upgrading airflow control from "passive response" to "active prevention."

From small household appliances to large industrial equipment, the gas pressure switch always works silently as the "invisible Airflow Commander." It has no gorgeous appearance, yet it makes invisible airflows orderly and controllable with precise perception and decisive orders; it has no famous reputation, yet it plays an indispensable role in the battlefield of safeguarding safety and improving efficiency. Next time you use a gas water heater or an integrated stove, you might as well think about this "little commander" hidden inside — it is because of it that every airflow is guarded for your safety and stability.