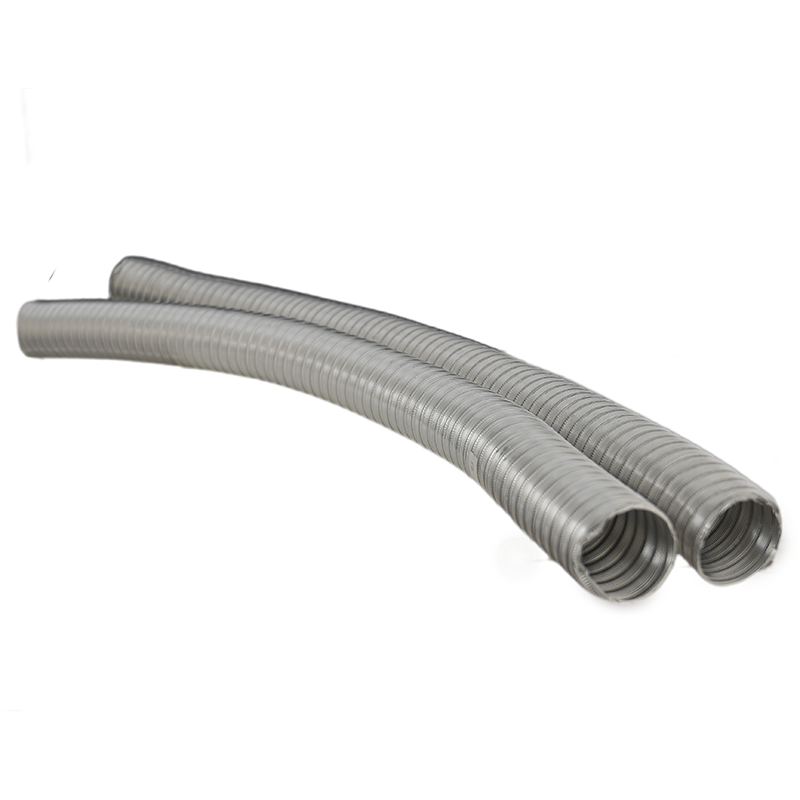

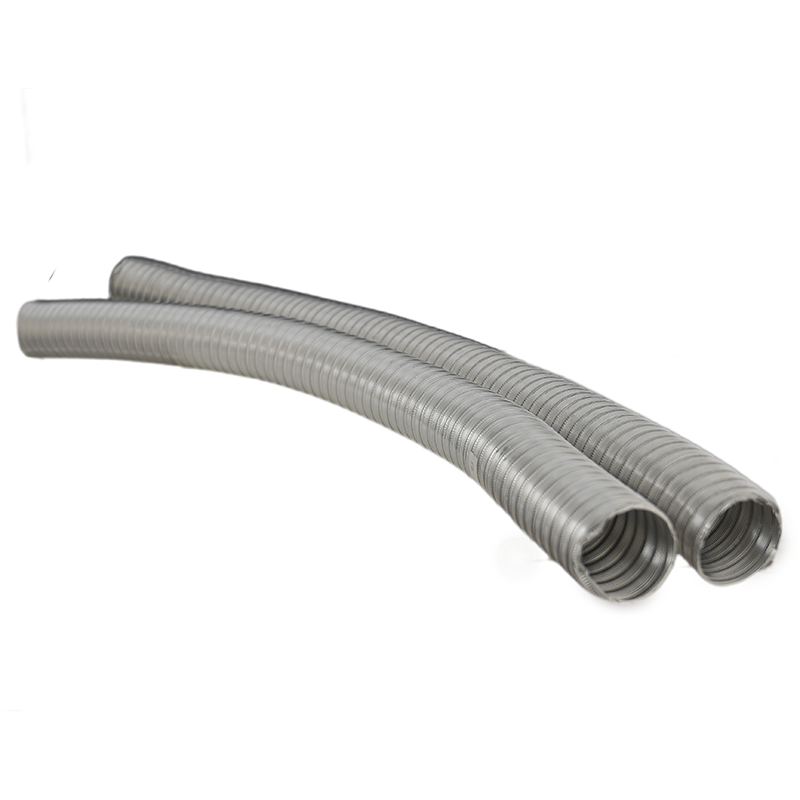

In the world of industrial piping and home heating, rigidity isn't always the answer. While a standard straight stainless steel pipe offers strength, it lacks flexibility. This is where the Stainless Steel Corrugated Metal Hose shines. It combines the durability of traditional stainless steel pipes with the ability to bend, absorb vibration, and fit into tight spaces.

Whether you are fixing a car exhaust or installing a home heating system, understanding the uses of this flexible stainless steel pipe can save you time and money. Here are the top applications where corrugated metal hose is the superior choice.

1. Vibration Absorption in Exhaust Systems

One of the most critical uses for corrugated hose is acting as a flexible stainless steel exhaust pipe. In automotive engines and industrial generators, vibration can crack rigid pipes over time.

By installing a corrugated section, you isolate the vibration. This flexible stainless steel exhaust pipe connects the engine to the rest of the system, preventing stress fractures. On a cold morning, when you see an exhaust pipe with smoke or vapor puffing out, you want to be sure the connection is airtight. A corrugated stainless steel exhaust pipe ensures that these fumes are directed away safely, even under intense engine shaking, keeping the exhaust pipe with smoke functioning correctly without leaks.

2. Flexible Connections for Water Heaters

Installing a water heater often involves working in cramped utility closets. aligning a rigid water heater flue pipe perfectly can be a nightmare. This is a primary use case for corrugated stainless steel.

Used as a connector for the water heater flue pipe, the corrugated hose allows for offsets and misalignments. It creates a secure, sealed path for dangerous combustion gases. Unlike aluminum, a corrugated stainless steel pipe resists corrosion from acidic condensate. If you are replacing a water heater flue pipe, using a flexible stainless steel section ensures a faster, safer installation that meets building codes.

3. High-Temperature Industrial Transfer

In factories, moving hot liquids or gases requires materials that won't melt. Standard rubber hoses fail under heat, and rigid stainless steel pipes are too difficult to route around machinery.

Corrugated stainless steel pipes solve this. They handle extreme temperatures just like a rigid stainless steel pipe but can snake around obstacles. Whether used for steam lines or chemical transfer, these hoses offer the same reliability as a solid stainless steel exhaust pipe but with the versatility of a hose.

4. Expansion Joints in Piping Systems

Metal expands when hot. Long runs of rigid stainless steel pipes can buckle under thermal expansion. Corrugated metal hoses act as expansion joints. They compress and expand, absorbing the movement.

This is similar to how they function as a water heater flue pipe or an automotive stainless steel exhaust pipe—they accommodate movement so the system doesn't break. When you see an industrial stack or exhaust pipe with smoke venting efficiently, there is often a corrugated section at the base absorbing the thermal stress.

Upgrade Your Piping System Today

Do not limit yourself to rigid materials. For applications requiring movement, heat resistance, and durability, a corrugated metal hose is the ultimate flexible stainless steel pipe.

Whether you need a durable stainless steel exhaust pipe for a generator or a flexible water heater flue pipe for your home, our corrugated solutions deliver.

[Shop Now] - Browse Our Flexible Stainless Steel Pipes