When selecting ventilation equipment for your HVAC system or industrial facility, you will often encounter the centrifugal fan. Unlike standard cooling fans that you might see on a desk, a centrifugal blower fan is designed for power and pressure. But how exactly does it work? Understanding the working principle of a centrifugal fan helps you realize why it is the superior choice for moving air through ducts, filters, and complex machinery.

The Core Concept: Centrifugal Force

Air Intake: The process begins when the impeller (the rotating blades inside the centrifugal fan) starts to spin. Air is drawn into the center of the fan, known as the inlet. Acceleration: As the air enters the center of the centrifugal blower fan, the spinning blades catch it. The impeller rotates at high speeds, throwing the air outwards towards the edge of the fan blades. This is where the centrifugal fan gets its name. Pressure Generation: This rapid outward movement creates kinetic energy (speed). The unique housing design of the centrifugal fan blower then captures this fast-moving air. As the air hits the curved casing, it slows down, and that speed is converted into static pressure. Discharge: Finally, the high-pressure air is forced out of the outlet at a 90-degree angle from how it entered. This concentrated stream of air is what makes centrifugal fans so effective.

Why This Principle Makes Centrifugal Fans Superior

Key Components of a Centrifugal Fan Blower

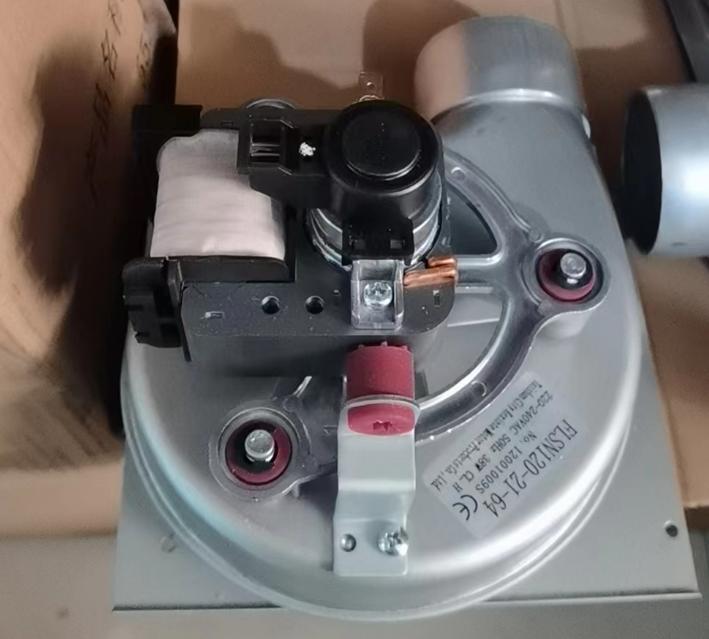

The Impeller: This is the heart of the centrifugal blower fan. The shape of the blades (backward-curved, forward-curved, or radial) determines the efficiency. The Housing: The scroll-shaped casing of the centrifugal fan is critical for converting the air's speed into useful pressure. The Motor: A reliable centrifugal fan blower requires a robust motor to maintain speed under heavy loads.

Applications Driven by this Principle

HVAC: A centrifugal fan is usually the engine behind your furnace or air conditioner, pushing air to every room in the building. Dust Collection: The high suction pressure of a centrifugal blower fan makes it perfect for sucking up sawdust and industrial particles. Industrial Cooling: Centrifugal fans can direct a focused stream of cool air onto hot machinery or products.