Beside the high-temperature pipelines in petrochemical plants, inside the dusty workshops of iron and steel smelting, and among the vibrating equipment of heavy machinery—the "harshness" of industrial sites is never just a figure of speech. High-temperature baking, medium corrosion, continuous vibration, and dust impact—any failure in a connection link may lead to leaks, shutdowns, or even safety accidents. In these extreme environments, what is needed is not only a "sturdy" connection, but also one with "flexible" adaptability, capable of stably transporting media, absorbing vibrations, and adapting to displacements under severe conditions. At this point, the thickened stainless steel corrugated metal hose becomes the most reliable "flexible connection" partner in industrial sites, tackling complex challenges with its robust performance.

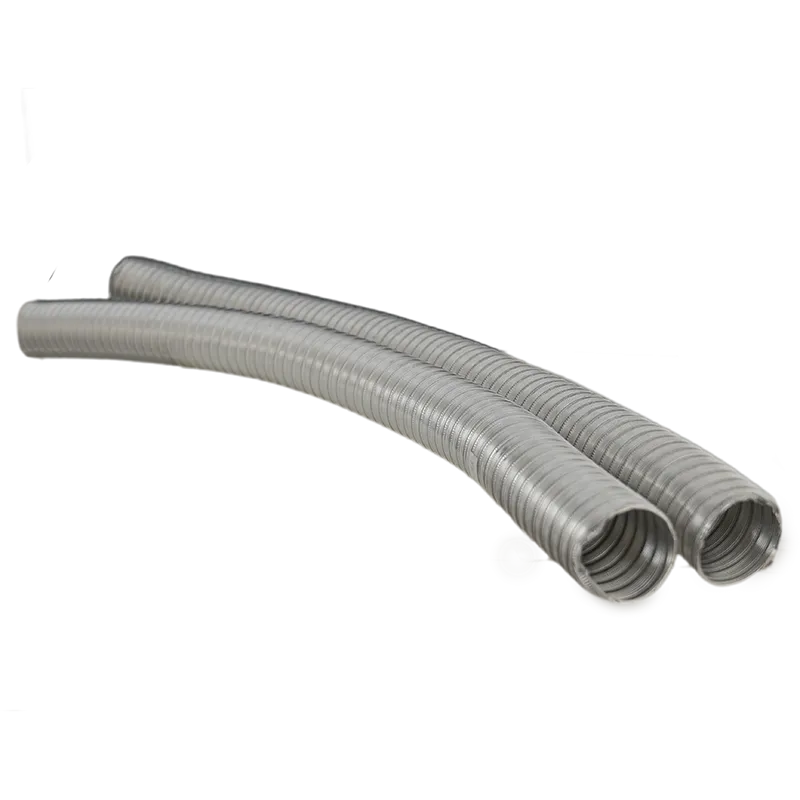

Its "reliability" first stems from the dual upgrading of material and structure. Different from ordinary metal hoses, this thickened stainless steel corrugated metal hose uses high-quality 304 or 316L stainless steel as the base material, with a wall thickness increased by more than 20% compared to conventional products. It can not only resist the erosion of corrosive media such as strong acids, strong alkalis, and high-temperature oil and gas, but also withstand extreme temperature fluctuations from -200℃ to 600℃. Even when exposed to long-term high-temperature baking or low-temperature freezing environments, it will not suffer from brittleness, deformation, or other issues. Meanwhile, the corrugated structure of the hose is precisely calculated— the height and spacing of each corrugation comply with mechanical design principles. It not only retains the rigid support of metal materials, but also possesses excellent flexible scalability, enabling multi-dimensional displacement compensation in axial, lateral, and angular directions. This allows it to easily cope with vibration displacements during equipment operation and pipeline installation deviations, avoiding the risk of fracture caused by stress concentration in rigid connections.

In terms of anti-vibration and anti-leakage performance, it is even more a "reassurance" for industrial sites. Continuous vibration during the operation of industrial equipment is an "invisible killer" for pipeline connections—ordinary hoses are prone to loose interfaces and cracked walls due to vibration fatigue. However, this thickened stainless steel corrugated metal hose adopts a double ferrule or welded sealing design at the interface. Combined with the anti-fatigue property of the thickened wall, it can disperse the stress caused by vibration to the entire corrugated structure. Tests have shown that it can withstand more than one million vibration cycles without leakage. At the same time, the inner wall of the hose is smooth, without burrs or dead corners, which can reduce the resistance during medium flow and avoid blockages caused by impurity accumulation. Whether transporting high-pressure oil and gas, high-temperature steam, or corrosive liquids, it can maintain stable sealing performance and eliminate safety hazards caused by medium leakage.

In addition to its robust performance, its adaptability also allows it to "thrive" in diverse industrial scenarios. According to different on-site needs, the hose can be customized with different lengths, calibers, and connection methods (such as flanges, threads, quick connectors, etc.). It can not only adapt to the high-pressure pipelines of large petrochemical equipment, but also meet the precision connection requirements of small instruments. Moreover, the stainless steel material itself has good wear resistance and dust resistance. In dust-intensive scenarios such as mining and cement production, it can operate stably for a long time without frequent maintenance, significantly reducing on-site operation and maintenance costs.

From the connection of reaction kettles in petrochemical industry, to the adaptation of hot air pipelines in steel plants, and then to the transmission of hydraulic systems in heavy machinery—this thickened stainless steel corrugated metal hose, with its characteristic of "combining rigidity and flexibility", has become the "flexible connection" guardian in harsh industrial sites. It is not as "rigid" and fragile as rigid pipelines, nor as "fragile" as ordinary hoses. Instead, with the durability of thickened materials, the flexibility of corrugated structure, and the reliability of sealing design, it builds a stable medium transmission channel in extreme environments. It answers with strength: in the harshest industrial sites, it is undoubtedly the most reliable "flexible connection".